- What Is A Torque Multiplier And How Does It Work

- Advantages of Torque Multipliers

- Types Of Torque Multipliers

- 1. Hydraulic or Electric Torque Multiplier

- 2. Pneumatic A.k.a Air Pressured Multipliers

- 3. Manual or Mechanical Torque Multipliers

- Are Torque Multipliers Dangerous?

- Can Torque Multipliers be Used With Torque Wrench?

Smarter solutions of ever-evolving technology are making it easier to perform difficult tasks with greater ease. A torque multiplier is an excellent example of smart technology solution. Tightening or loosening nuts, bolts, and screws not only requires the operator to use a lot of force and energy but also involves elbow grease.

Moreover, traditionally, extended handles are being used to apply greater torque. Extended handles, which are often referred to as “cheater bars,” use leverage to reach optimal levels of torque, which can be very dangerous at times if the driver tool attached to the extended handle fails disastrously, as a consequence of which they are not considered an ideal solution to generate torque.

Torque multiplier is an excellent alternative to extended handles. It is pretty safe to use as it provides only a small amount of torque pressure on the driver tool. Additionally, with the help of this device, both the lever length and the operator’s effort can be greatly reduced. It is found that the reduction in lever length and operator’s effort by this multiplier can be by a factor of 5, 20, or 25.

In this article, we will look at what is a torque multiplier and how does it work. This information will help you decide whether you need such a tool or not. It will also address your queries related to this particular device. So, let’s get started.

What Is A Torque Multiplier And How Does It Work

A torque multiplier is a mechanical tool that helps its operator to apply greater torque without requiring any extra force or pressure. With the help of a torque multiplier, greater torque is generated than would normally be applied by the operator. It is a safer and better alternative to long wrench handles. Torque multipliers are particularly helpful in breaking stubborn bolts and nuts.

Additionally, it has been found that torque accuracy increases if pressure is applied smoothly and slowly, which is why multipliers are immensely useful as they eliminate much of the physical effort from the tightening job.

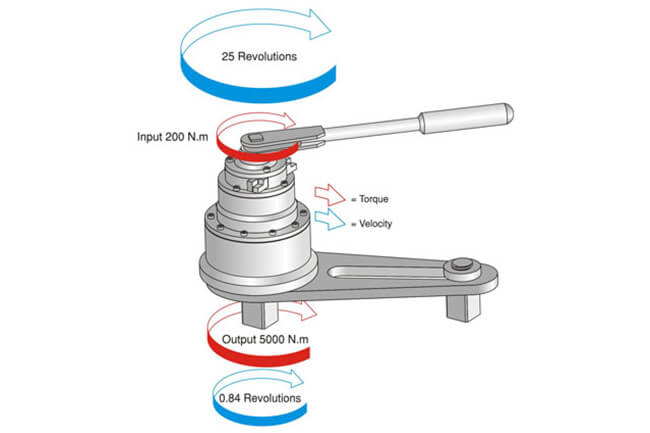

Torque multipliers make use of an epicyclic gear train having one or more stages. Applied torques are multiplied with each stage of the gear train. An epicyclic gear train system involves applying torque to the input gear or sun gear, making the planet gears rotate surrounding the sun gear. The planet gears are kept together in a planet carrier which clings to the output driver shaft too.

The rotation of planet gears around the sun gear makes the carrier and output shaft rotate together too. There is a reaction arm to prevent the rotation of the outer casing, without which the outer shaft cannot apply torque.

A torque multiplier works not only by multiplication of torque but the rotational speed of the output shaft is much less than the input shaft, which also increases torque. There are several reasons why this tool is preferred over cheater bars or wrench with extended handles, and a few of them are:

- Sometimes, the nuts and tools are closed so tightly that a simple wrench with an extended handle cannot help to loosen them.

- Cheater bars are not always practical, especially in places that have space limitations, making torque multiplier a better choice.

- Use of this tool is safe in comparison to cheater bars.

Advantages of Torque Multipliers

Torque multiplier has many advantages, some of which are:

- It comes with the capability to manage the amount of effort required, making it more in control to generate exact torque levels.

- It saves time and money by ensuring the bolts are not closed too tight or too loose with the help of slow and measured motion.

- It greatly increases the productivity and efficiency of operators as it substantially reduces the amount of effort required by them.

- It reduces the maintenance costs and nearly eliminates the need for repairs or readjustments by making sure the nuts are tightened and loosened properly.

- It is very lightweight and hence can be easily transported, making it a highly portable solution, which is an essential requirement for many industrial users.

- It does not cause any wear and tear.

- It requires very little space.

- They are easy to use.

Types Of Torque Multipliers

There are three different types of torque multipliers: hydraulic or electrical torque multipliers, pneumatic torque multipliers, and manual torque multipliers. The first two types of torque multipliers are operated electronically, while the third, as the name suggests, is manual. Each type of torque multipliers has its own advantages and disadvantages.

1. Hydraulic or Electric Torque Multiplier

This is the type of torque multiplier that uses hydraulic pumps to create high torque levels. To ensure that the bolts get just enough force, they require to fasten or loosen; the hydraulic torque multiplier controls and adjusts the torque level with the help of sensors.

Hydraulic or electric torque multipliers are particularly useful in situations where torque multipliers are used quite extensively, and the use of a manual multiplier can be burdensome.

This type of multipliers is mostly suitable for factories and automobile garages, where manual multipliers cannot be used to certain limitations such as short windows and limited space. Additionally, electricity is used by these multipliers to produced optimal torque volume, which is nearly impossible to be produced by its manual counterpart. The use of electricity greatly reduces the amount of effort required by the operator.

However, when there is this added advantage of more power, there is a limitation to finding electricity to charge the tool. A battery-operated torque multiplier is a convenient alternative as it not only eliminates the requirement of electricity, but it also makes the machine portable.

There is one thing that needs to be taken care of is to charge and replace the batteries. While on the other hand, electric-powered multipliers can provide consistent power for a longer period of time. In a nutshell, we can say that both electric-powered and battery-powered multipliers have their own advantages and disadvantages.

2. Pneumatic A.k.a Air Pressured Multipliers

This is the most costly and most highly developed multiplier amongst all the other three types of multipliers. It uses electricity and air pressure to create the torque required to loosen or tighten the nuts and bolts. This type of multipliers is most extensively used for heavy machinery, large vehicles such as buses and trucks, and industrial machinery.

Since manual multipliers occupy a lot of space that might not be practical in many cases, a reason has given rise to the popularity of pneumatic multipliers. However, these multipliers with a hefty price tag, and they require the availability of both air compressor and electricity.

3. Manual or Mechanical Torque Multipliers

Manual torque multipliers are the most widely used type of torque multipliers. Since they were invented long before both pneumatic and electric multipliers, therefore they are trendy. This type has many advantages over the other two types of multipliers. Firstly, they do not require air pressure or electricity, which makes them affordable and practical to use.

Secondly, they do not require much maintenance, making them a greater choice for those looking for hassle-free solutions.

In the case of manual torque multipliers, torque force is generated with the help of a hand. Since it has a minimal mechanism and does not require air pressure or electricity, it makes it very lightweight, resulting from which it can easily be transported from one place to another. Manual multipliers come in many sizes, and their application varies from removing small vehicle bolts to tightening heavy-duty industrial bolts.

They are the cheapest amongst all other multipliers, but they are also most easy to use and convenient, ranking them highest in popularity.

Are Torque Multipliers Dangerous?

In fact, one of the purposes behind this invention was added security and ease of use. The torque multipliers are completely safe to use as they eliminate the need for long handles, which can be quite dangerous at times. They can be used with any risks of bolts coming off or fear of any other injury caused to the operator.

Can Torque Multipliers be Used With Torque Wrench?

Torque multiplier is indeed an advanced form of torque wrench. Traditionally torque wrench comes with extensions for more complex tasks such as tightening and fastening heavy-duty bolts, which require long handles. Torque multipliers replace the need for extensions, and the same functionality can be provided with one single device with more efficiency and productivity.

Also, there are circumstances where space is limited, and torque wrench cannot be used; this is where torque multiplies take their place, attributing that they do not have long handles. They are not only handier than torque wrenches, but they are more efficient as well.

Lastly, they are situations where bolts and nuts are closed so tightly that the torque wrench would not work on them, again giving rise to the need for a torque multiplier. Having said that, there are situations where the task might require a wrench and multiplier together.

High Pressure Water Hose Guide

Contents Can You Use a Normal Hose for a Pressure Washer? Does Hose Diameter Affect Pressure? How do I make my garden hose high pressure?

What Is High Pressure Hose Used For?

Contents What is high pressure hose used for? How much PSI do I need to clean my driveway? What PSI is best for washing cars?

Rechargeable Hot Water Bottles Guide

Contents Are rechargeable hot water-bottles safe? How often should you change your hot water-bottle? How long does a rechargeable hot-water bottle last? How do Electric

Will A Heating Pad Ruin A Memory Foam Mattress?

Contents What is a Heat Mattress? Will a Heating Pad Ruin a Memory Foam Mattress? Buy Heating Pad on Amazon Conclusion One of the things

How Do You Clean A Suckle Portable Bottle Warmer?

Contents How does a suckle bottle warmer work? Do I need a bottle warmer if breastfeeding? How do you clean a suckle portable bottle warmer?

3 Tips for Take Care Lawn You Need to Know

Contents Is It Better To Water Lawn in the Morning or at Night? How Many Days a Week Should You Water Your Lawn? Should You

Emily

Head of Content @NotJustType I am a shopaholic and I am here to use my shopping experience and life skill to share to everyone. If you have any question for life, home, garden, you can let me know!

Share this article

Subscribe for weekly updates